StressWave

StressWave Technology

Power & Process Products and Services

Predicting Failure

StressWave is an advanced condition monitoring system for detecting

wear and damage before it becomes excessive, tracking the change over time,

and predicting when the damage is likely to result in equipment failure so

that maintenance can be scheduled before failure occurs.

There are generally two maintenance strategies employed in

industrial settings and in the power generation industry;

periodic and run to maintenance. With periodic maintenance,

often called preventative maintenance, the frequency of maintenance

is based on minimizing the likelihood of an unplanned outage due to

failure of equipment occurring before the next scheduled maintenance.

Run to maintenance, which is really the more dreadful sounding run to

failure, is often used when system redundancy allows plant operations

to continue even after component failure.

What are Stress Waves?

Stress waves are acoustic waves that propagate through solid

components.

The source of the stress waves are primarily the impacts and

collisions that occur due to surface defects, cracks, voids,

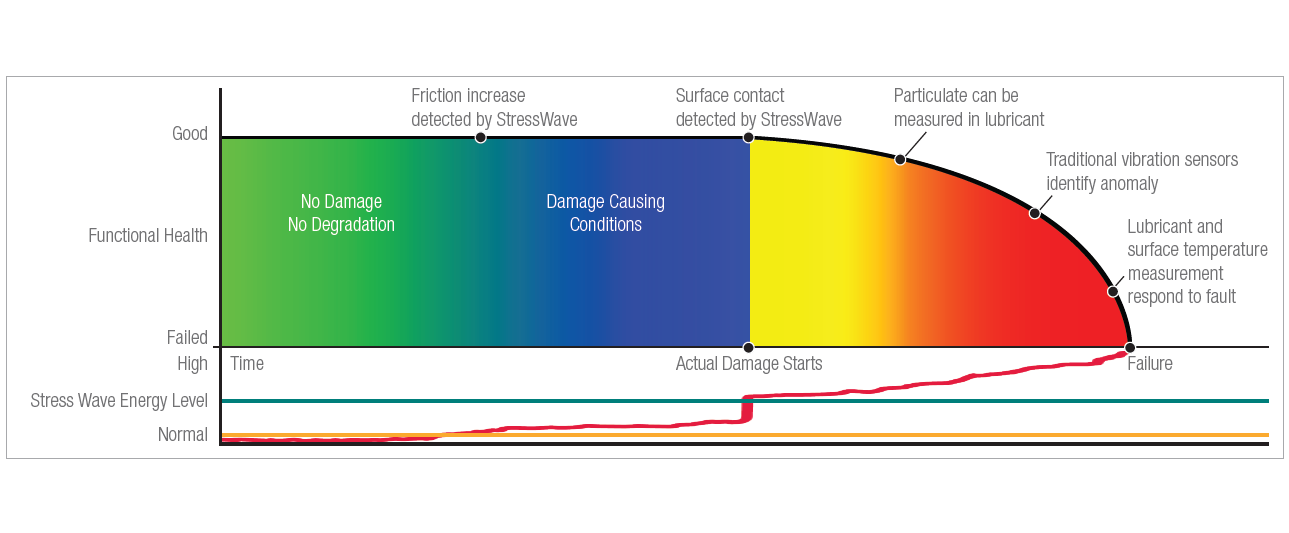

excessive wear, corrosion, or other damage. Damage that occurs

to components such as ball bearings tends to increase exponentially

over time. Operators typically do not need highly sensitive equipment

to detect failure that has already occurred. The goal of predictive

maintenance is to measure and track the condition of bearings and

other components such that failure can be predicted allowing maintenance

to be scheduled at a convenient time before failure has occurred.

The stress waves targeted are not audible sound. Both the

frequency and amplitude are well outside the range of human

hearing. Wear and damage sufficient to create audible sound

above and beyond normal equipment sounds likely means excessive

damage has already occurred.

How it Works

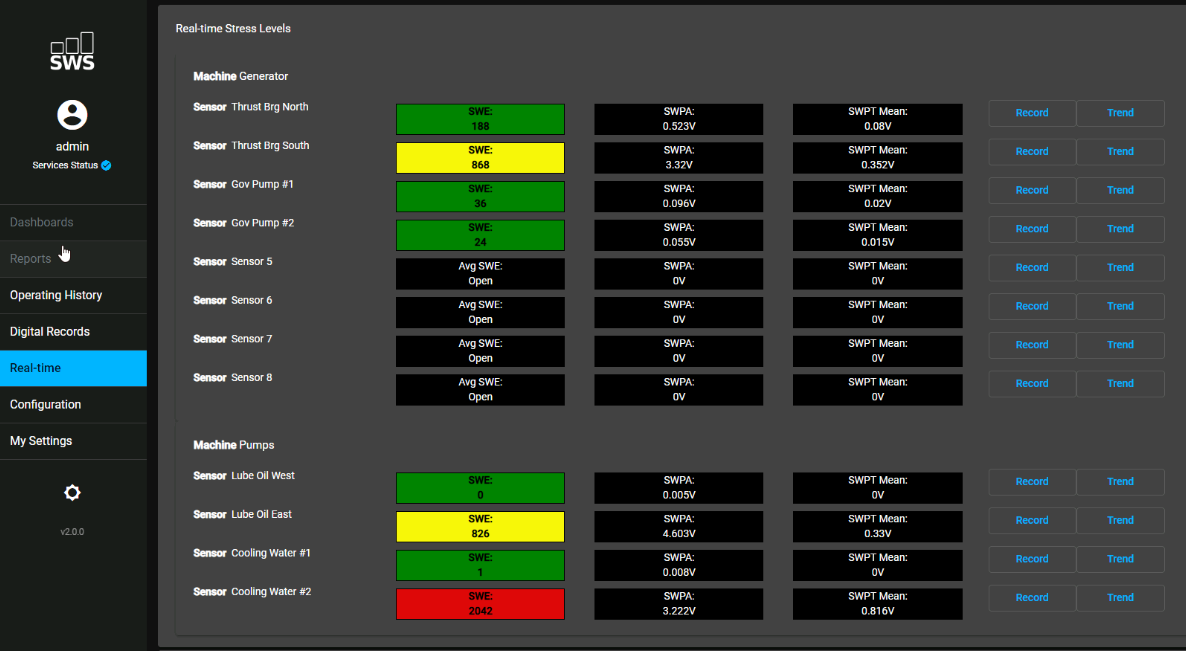

The StressWave system employs distributed data acquisition

units and special patented sensors that monitor high frequency

sound generated by friction between moving machine components.

This technique provides a higher degree of dynamic resolution

and more failure lead-time than traditional diagnostic methods.

Imagine a flawless ball bearing spinning in a controlled environment

at 5,000 RPM and the sound such a bearing might make. Now imagine

that bearing has a tiny defect or excessive wear and the additional

sound the bearing might make. The delta between the sound created by

the flawless and damaged bearings represents the magnitude of damage

and when plotted can be used to predict when catastrophic failure is

likely to occur. Now imagine that bearing being at the end of a

turbine driven feed pump shaft, with 8,000 gallons per minute of

350°F water flowing through it. Before the delta between the

flawless and damaged bearing can be determined, the challenge

is to first separate the bearing noise from all of the other much

louder sounds generated within the pump and from other nearby plant equipment.

The specially designed piezoelectric sensor is used with a resonant

frequency that is tuned to a specific frequency within a band where

stress waves occur. The sensor signal is processed by a data collector

using proprietary filtering algorithms to focus in on stress waves representative

of the machine’s operational frequencies.

The Benefits

The downside to periodic maintenance is that maintenance is on

average performed prematurely, increasing the long-term maintenance

costs to the plant. The downsides to run to maintenance are that

failures are likely to occur at inconvenient times and damage to

equipment may occur as a result of the failure that was permitted

to happen. Plants choosing either of these maintenance strategies

are selecting the lesser of two evils.

The solution to performing maintenance too soon or too late

requires the ability to accurately predict when failure is

likely to occur. Curtiss-Wright’s StressWave technology does just that.