Predictive Pattern Recognition (PdP)

FAMOS Solutions

Power & Process Products and Services

A critical part of your maintenance management strategy

PdP is a superior, advanced pattern recognition application for

condition monitoring to improve equipment reliability. PdP utilizes

existing data signals available through installed DCS systems,

historians, and other monitoring systems for early detection of

abnormal operating conditions.

The System State Analyzer algorithm embodied in PdP produces

very accurate estimates of the expected values of sensors utilizing

models that have “learned” the normal operation of the equipment

based on historical performance.

The estimated values are compared to the real time values to evaluate

overall system operation before extreme problems take hold of your operation.

There are a number of compelling reasons to consider PdP for protecting your

plant or fleet. The value of predictive analytics lies in your ability to

gain greater control over your operation by receiving clear, advance warning

of equipment or process degradation.

PdP works to your advantage by:

- Addressing equipment and instrument problems early – to reduce control room alarms and enhance plant productivity

- Shifting unplanned outages into planned maintenance work to help you better manage operating expenses and maximize reliability during peak production periods

- Reducing the risk of catastrophic failure, protecting plant personnel and equipment

- Reducing maintenance costs by incorporating real time equipment health information into condition-based maintenance programs

- Saving millions of dollars by routine daily usage with payback within months as documented in client case histories

Curtiss-Wright’s PdP, in conjunction with the other FAMOS condition monitoring tools, provides efficient, superior equipment protection.

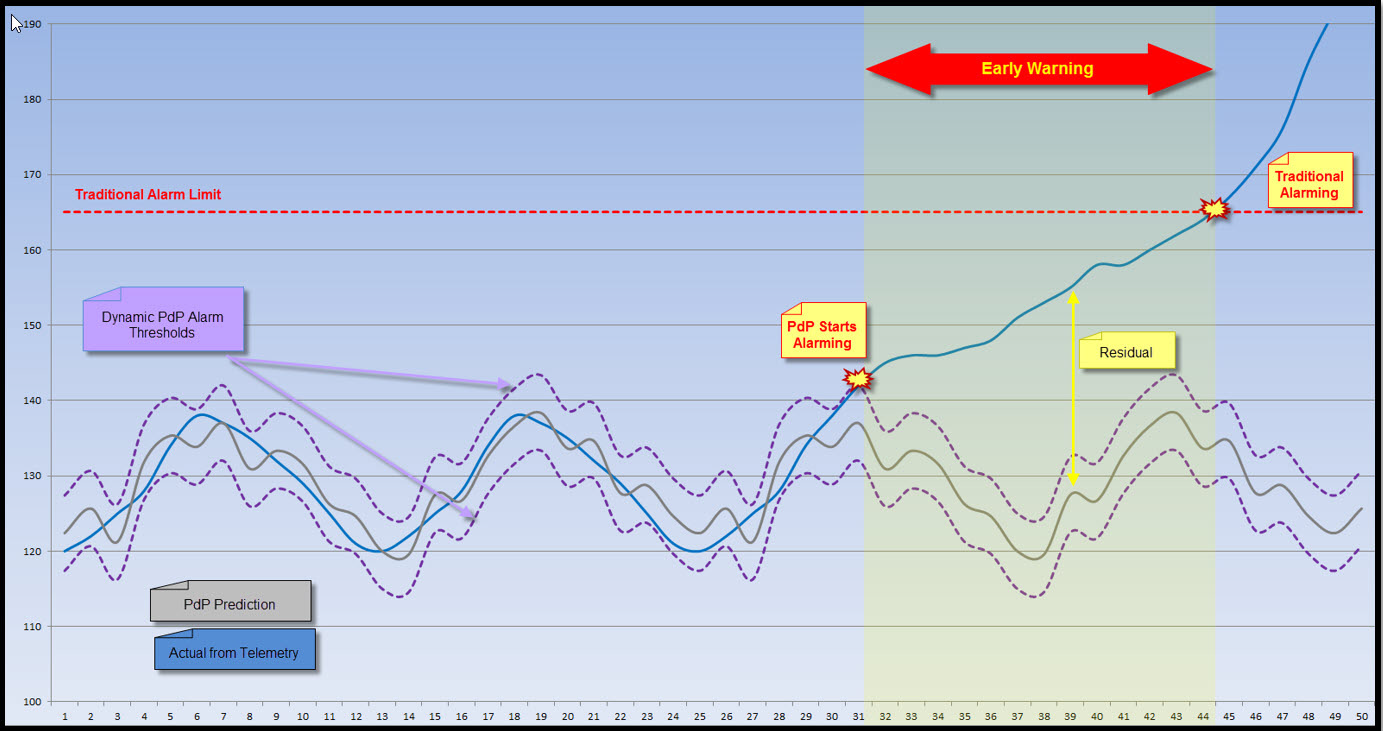

Early warning

The Curtiss-Wright approach optimizes your performance

Every application in the FAMOS suite is readily deployed

and designed to ensure ease of use and utility. Product

features that help deliver a maximum return on your investment include:

- Straightforward alarms that identify system and equipment anomalies

- Clear equipment and process displays that outline remedies and simplify corrective action planning

- Exceptional reporting and review functionality via web, e-mail, and/or console

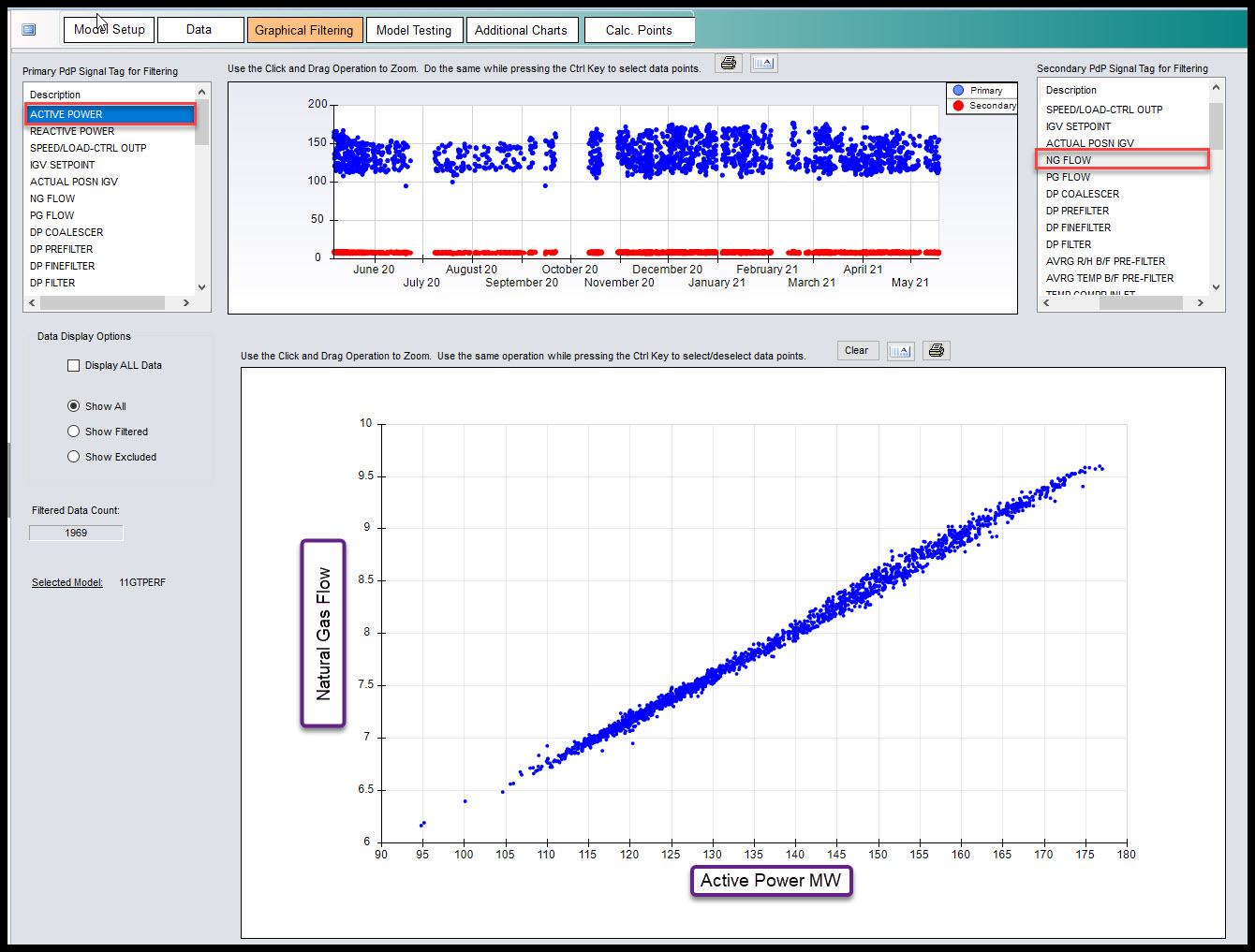

- User-friendly “FAMOS Architect” graphical tool for ease in building, training and testing models

Because PdP is created by the same developers as other FAMOS suite products

it creates an integrated and robust solution for your plant or entire fleet –

when installed as part of the suite.

Efficient model training

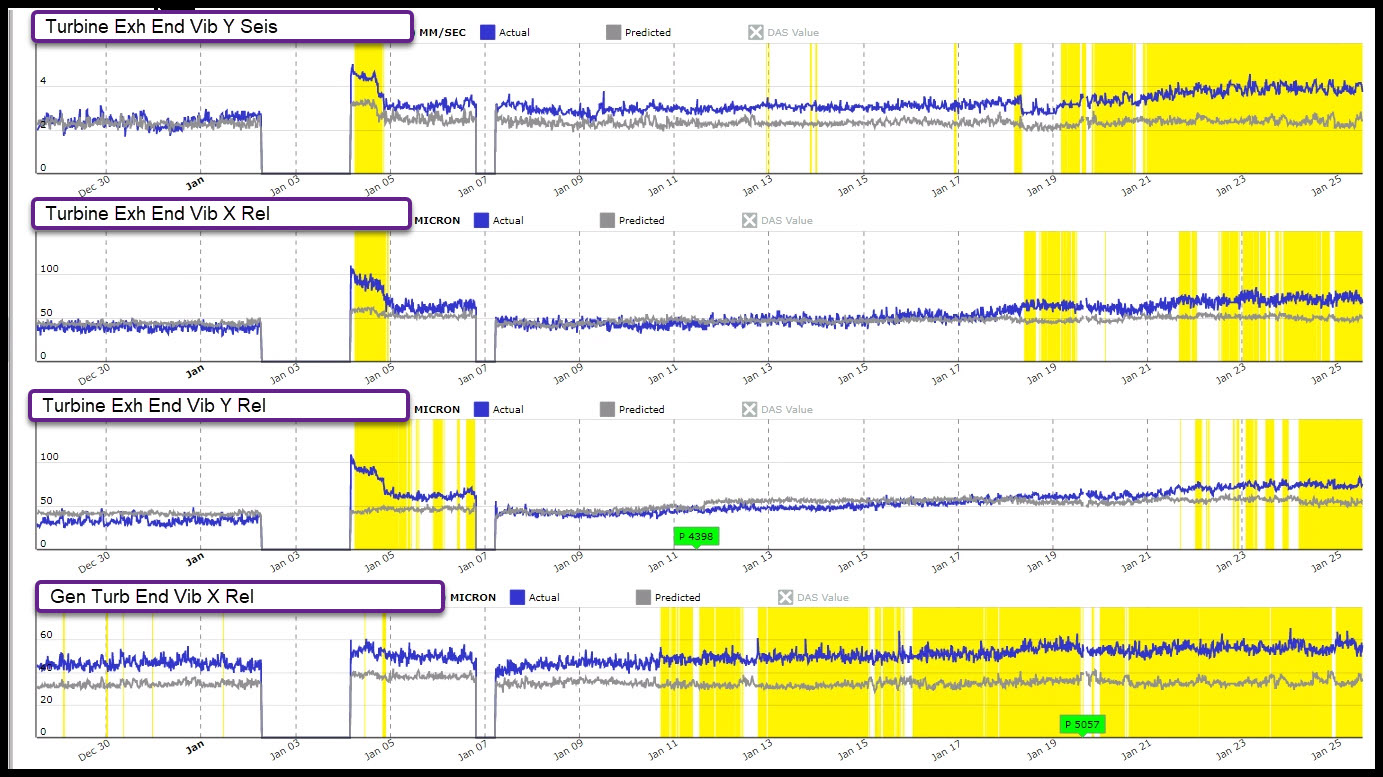

Gas turbine vibration changes identify developing bearing fault