PEPSE

Plant Modeling and Simulation Software

FAMOS Suite of Products

About

Curtiss-Wright is a global integrated company with a long tradition

of providing state-of-the-art, reliable solutions through trusted

customer relationships.

The Plant Optimization Group, a business unit within Plant Information Monitoring

and Control, provides a variety of products, services, and software-related

solutions to the global power industry. We are leaders in thermal performance

software and services; equipment reliability solutions; valve condition monitoring;

and advanced data analytics. We further enhance our customer support through our

Monitoring and Diagnostic Center providing remote detailed evaluation of the

condition of clients’ assets.

We are committed to the safe operation and improved performance and reliability of power plants worldwide.

Digital Twin

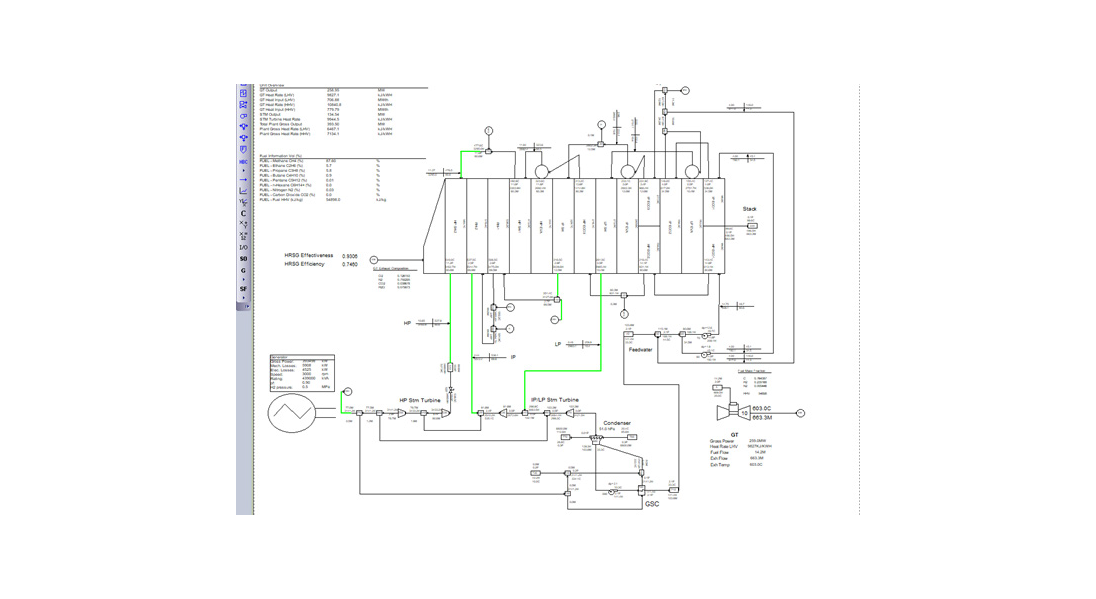

PEPSE is a Windows-based, drag-and-drop, steady-state energy balance

software package that is sophisticated, yet easy to learn and apply.

It allows the user to simulate a modular representation of a plant’s

thermal processes including component hardware and piping systems.

Plant performance is then calculated through the user-created schematics

that mimic your plant’s thermal operation and configuration.

When engineers have the ability to readily and accurately analyze and

optimize a system’s efficiency, the operation derives a number of direct

and important benefits.

PEPSE is the key to:

- Accurately analyzing plant performance and identifying ways to increase generation and reduce your fuel cost

- Eliminating causes of inefficiency and conserving every possible kilowatt and BTU

- Reducing plant emissions and carbon footprint

- Lowering your operating costs through higher efficiency, fewer repairs, less downtime and lower fuel costs

- Granular modeling provides confidence in the accuracy of plant assessments of proactive decisions

PEPSE has a number of different modes, allowing

its use as a tool for conducting a range of studies:

- Compare actual data to expected values

- Evaluate the system affects of changes in operating arrangements, in performance indicators, or in individual component modifications

- Analyze test data as specified in ASME® performance test codes

PEPSE provides engineers with integrated performance data and the means

to construct detailed system models for evaluating heat rates

and plant performance.

The functioning of controllable parameters in a plant – equipment condition,

system interaction, steam operation, gas and other fluid systems –

all contribute to its overall efficiency.

PEPSE has been installed in over 700 generating units over the past 40 years

and is the industry standard in thermal performance monitoring.

PEPSE is the advanced computational tool for easy and accurate analysis

In addition to evaluating overall plant performance, PEPSE will let the user perform a host of other

important tasks. Additional ways to employ PEPSE include:

- Isolate individual component performance – pinpoint specific hardware malfunctions before they escalate and create costly systemic problems

- Evaluate potential design modifications – before new systems or equipment investments are made

- Determine desirable cycle heat rates for new nuclear, fossil, or combined cycle units or for changing fuel sources

- Audit NSSS, boiler, heat exchanger, feedwater heater, condenser, HRSG, or turbine vendor (steam or gas) claims during a proposal evaluation

- Perform “What-If” analyses to determine effects of operational changes and conducting plant degradation studies, plant data reductions, and incremental heat rate calculations.

PEPSE provides integrated performance data and the means to construct detailed system models

PEPSE can be readily employed to test any part of your plant system: hydraulic parameters,

equipment hardware, cycle piping arrangements, component characteristics, and ambient

conditions. With this ability to monitor a full range of operating variables and conduct a

comprehensive assessment, the power to affect overall plant efficiency increases.

Easily and accurately analyze your entire plant, a

portion of the facility, or individual components

Easily and accurately analyze your entire plant, a

portion of the facility, or individual components

PEPSE may be used as both a standalone program or in a network environment. It also allows

interaction and data transfer and results between other software programs such as PEPSE-RT,

Excel® and Visual Basic®.

Easily and accurately analyze your entire plant, a

portion of the facility, or individual components

Easily and accurately analyze your entire plant, a

portion of the facility, or individual components

Cost-savings reported in an independent study of PEPSE users

| $3,500,000 saved on a planned boiler modification upgrade |

| $12,000,000 saved on a turbine replacement |

| $250,000 average operating cost savings per year |

The power of integrated support