Equipment Anomaly Detection (EAD)

FAMOS Solutions

Power & Process Products and Services

What is EAD?

Equipment Anomaly Detection (EAD) is a neural network based application for

detecting equipment anomalies. EAD automatically learns relationships between

hundreds of equipment parameters. EAD models are easily updated as new normal

operating conditions are encountered and can provide contextual data for easy

action planning or other disposition. EAD can be an ideal option in certain

operational conditions, such as when limited domain expertise is available

for initial model build, model training, and general day-to-day use by system engineers.

A System for Detecting, Evaluating, And Dispositioning Potential Equipment Anomalies

The EAD system will:

- Help identify early indications of equipment failures

- Improve equipment reliability

- Allow preventative actions to mitigate failure

- Detect anomalies and deviations from the standard operating parameters of the equipment

- Indicate the beginning of an equipment failure

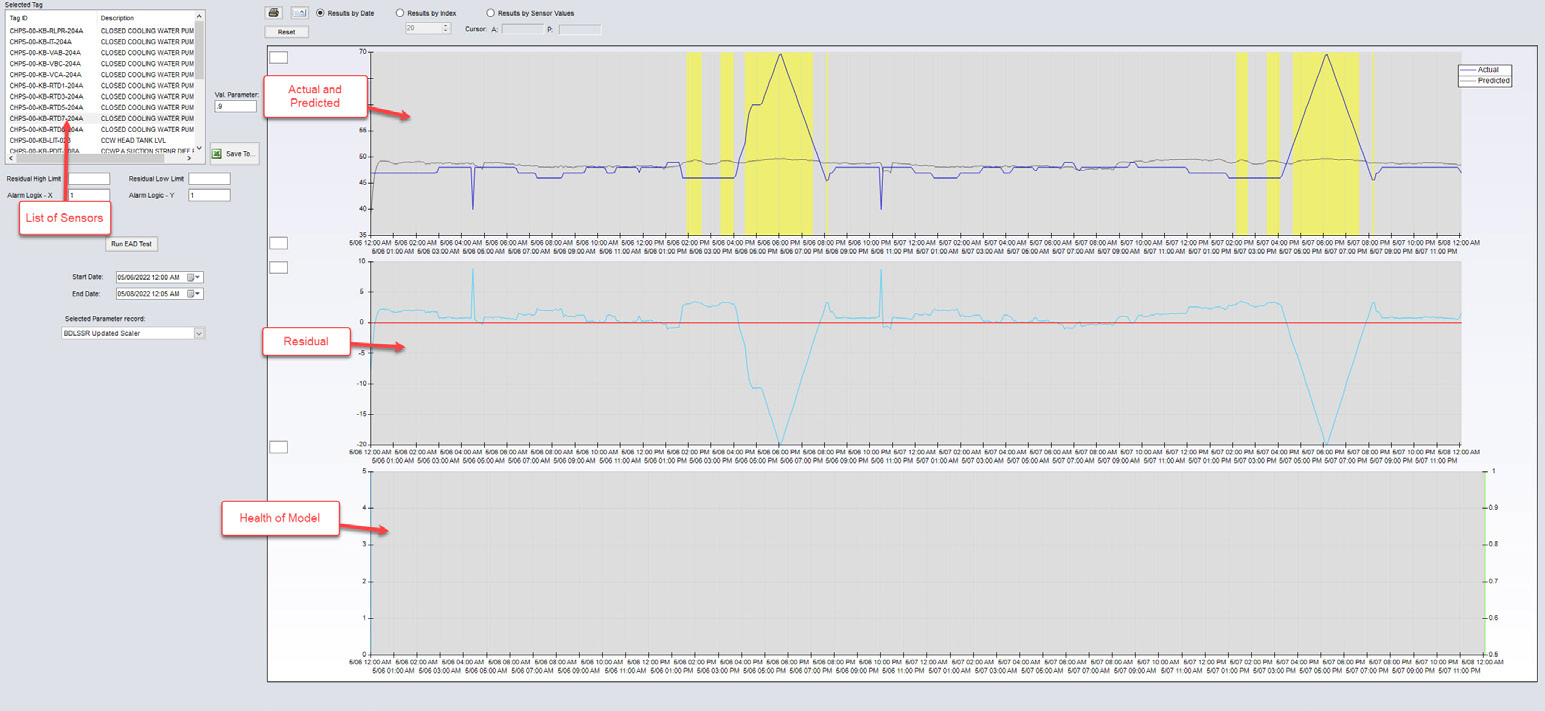

Example of Equipment Anomaly Detection (EAD) Summary

How does EAD work?

EAD uses a specific type of artificial recurrent neural network (RNN) architecture

composed of long short-term memory (LSTM) autoencoder units. This architecture

has demonstrated success in producing expected values for its collection of modeled

sensors based not only on the current dataset, but also upon the data from a configured

number of time steps into the past.

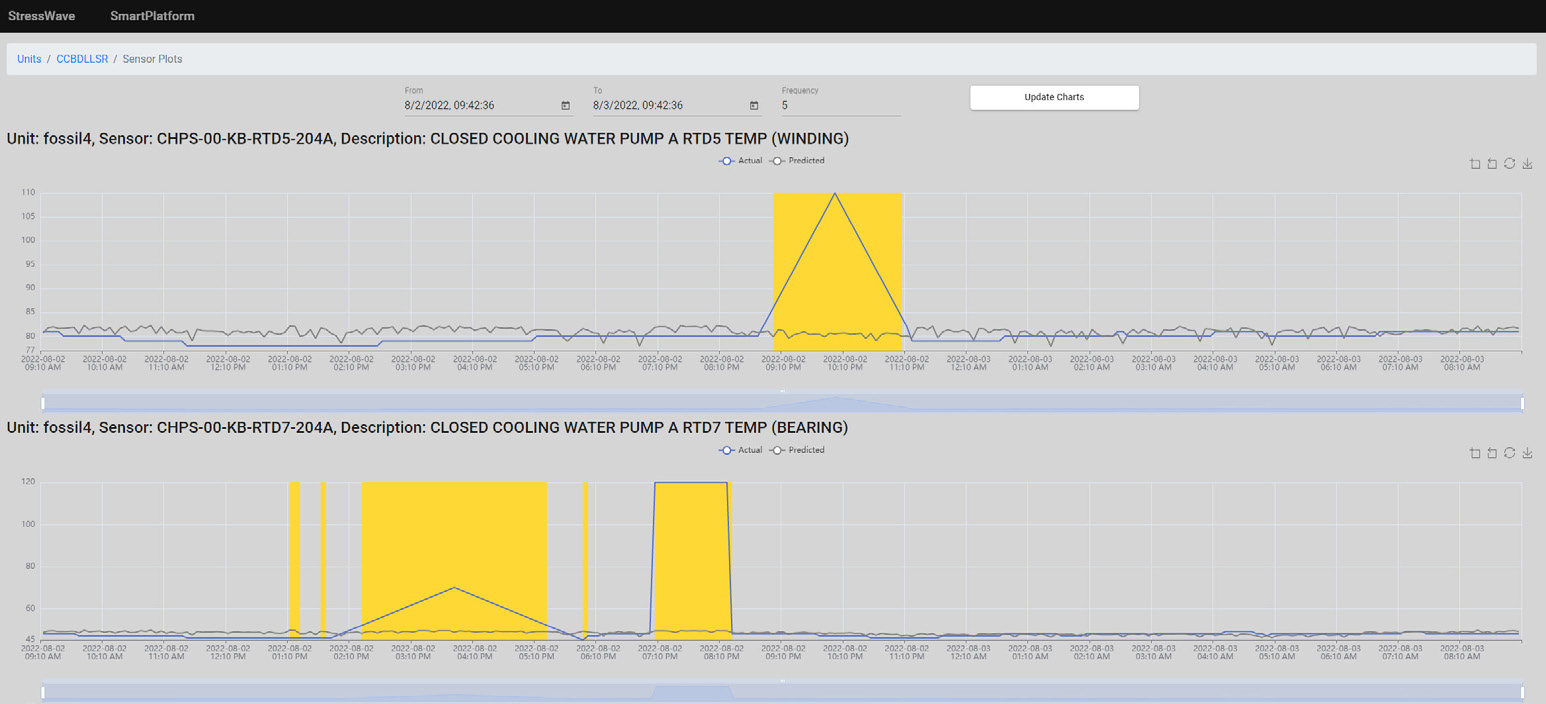

As such, EAD can effectively monitor transient behavior like startups,

shutdowns, and rapid operating changes that are more challenging for

similarity-based models like PdP.

In addition, RNNs can evaluate a large number of sensors, including vast

combinations of digital inputs. Combined, these features provide anomaly

detection functionality that is sensitive to degradation with few false-positive

indications.

EAD models are constructed and trained with historical data using

the same Windows based client as PdP—the Smart Platform Architect.

Trained models are deployed to the Smart Platform server

to produce runtime predictions.

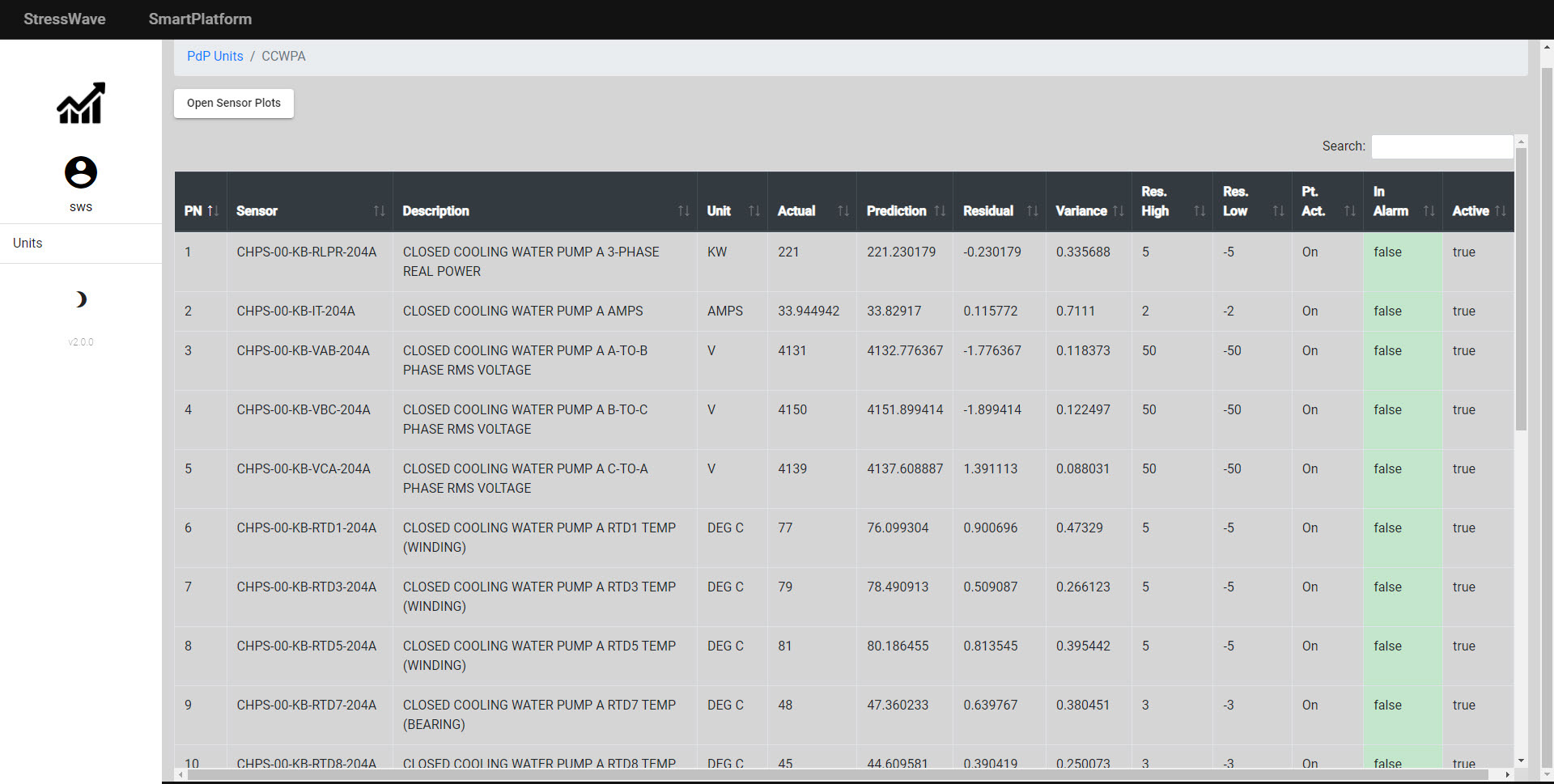

Real-time alarms and diagnostic tools are provided to end users

on the Smart Platform integrated web-based GUI alongside PdP and StressWave analytics.

Using historical data, EAD can produce robust, efficient models that can be

trained with little involvement from subject matter experts yet still provide

early warning of equipment failures with few nuisance alarms. EAD also includes

limited alarm functionality based on the deviation of individual sensor behaviors

from predicted values (residual) for any given snapshot of data.

In addition, the roadmap for future releases includes an integration layer

for retrieving contextual data (such as CMMS and logs), updating them according

to findings, and utilizing information derived in anomaly disposition.