PEPSE-RT

FAMOS Solutions

Power & Process Products and Services

Reliable data, proactive information, and powerful results

The Famos plant thermal performance monitoring system has been

widely adopted, with more than 300 commercial and industrial installations

around the world. Both plant operators and engineers benefit from the critical

information and readily accessible tools available. Key benefits derived

from employing the technology are:

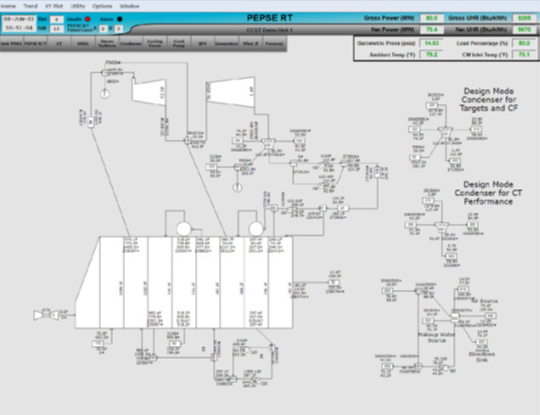

Comprehensive assessment of plant performance – PEPSE-RT detects abnormalities

at the system, component and instrument level and presents key performance indicators

and financial information to management, engineers and operators.

Flexible application – Designed to be used with conventional fossil,

combined cycle, simple cycle, nuclear and renewable energy processes. Custom calculations

can be readily developed to fit your plant needs.

Money-saving advantages – Increased generation and reduced heat rates,

fuel costs, and emissions with improved information to manage maintenance and outages more effectively.

Easy, reliable detection – Detects instrument fault

and calibration errors through our Input Data Validation Module (IVM).

Integrates with existing software –

PEPSE-RT is easily networked for information sharing across the

business LAN with unlimited user access; PEPSE-RT also links to

Excel for data sharing and reporting and to PEPSE for conducting “what-if” analyses.

Added value from best practices –

Developed by experienced engineers with plant and process knowledge

that includes integrated performance and condition monitoring modules.

World class and timely support –

Upgrades, technical assistance and training are available providing complete maintenance services.

Seamless integration with FAMOS condition monitoring tools

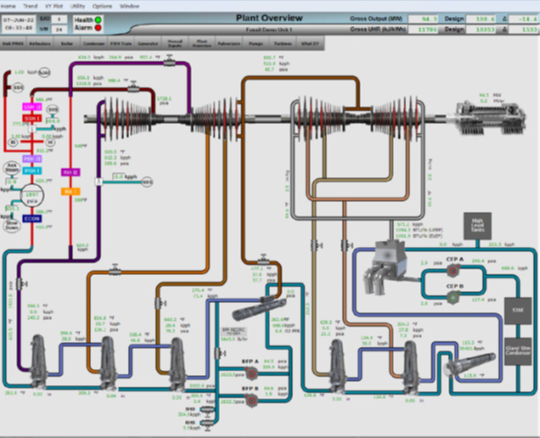

Plant operators and engineers have successfully monitored their facilities

with FAMOS for more than 30 years, using the array of tools

and numerous reports available through the popular PEPSE-RT system:

Historian and Trending –

Extensive custom data historian and trending system.

Data Integrity –

Granular modeling capability assures simulation

accuracy for detecting anomalies and performance degradation over time.

Reports and Diagnostics –

Reporting and diagnostic tools allow users

to easily view critical information and diagnose issues:

- Performance information in real time or over specific reporting periods

- Rules engine for capturing failure modes logic and fault trees for automated diagnostics including tribal knowledge of the aging workforce

- System diagnostics that identify software, instrument and data validation status

- Advanced alarm management system that provides comprehensive tools for instrument, component and system alarms

System Implementation –

Secure network installation for control room

and monitoring and diagnostic centers complying

with NERC CIP requirements.

Remote Monitoring and Diagnostic Services –

PEPSE-RT is a key application along with Advanced Pattern Recognition (APR)

providing enhanced performance and reliability metrics from Curtiss-Wright’s

remote Monitoring and Diagnostic Center for clients looking for added value.

Extensive Calculation Ability

The following is a sample of the many calculations available in a PEPSE-RT system:

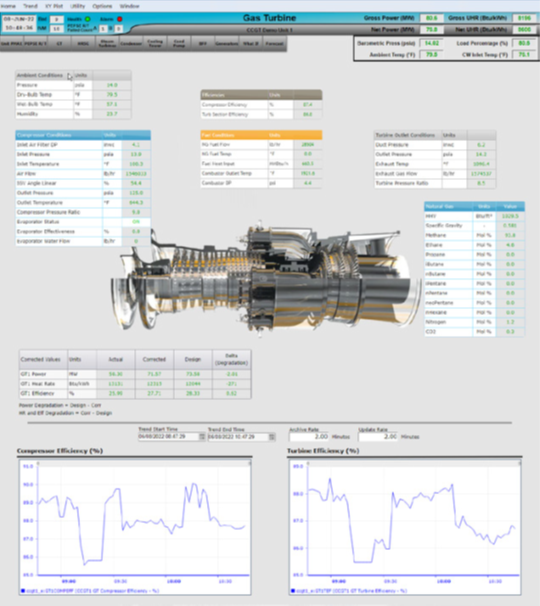

Performance Calculations

- Air heater performance

- Boiler efficiency (I/O and heat loss)

- Boiler soot blowing advisor

- Condenser performance

- Controllable losses/MW effects

- Cooling tower performance

- Feedwater heater performance

- Gas turbine performance

- Generator performance

- Heat exchanger performance

- Heat recovery steam generators

- Lost power advisor

- Moisture separator reheater performance

- Pump performance

- Steam generator performance

- Steam turbine performance

Sample Gas Turbine Display

Valuable Features

- 31 level security system

- 60,000 analog/digital point databases

- Advanced input data validation

- Display builder

- Excel® links including automated reporting

- Full trending/report package

- Independent data historian

- M&D center fleet wide designed

- OPC and ODBC connectivity

- Predictive what-if analysis

- Remote access tools (works with firewalls)

- Support programs (steam table add-ins and many more)

- System health log

Sample PEPSE-RT Overview Display

Minimize ramp up time with technical assistance and support

PEPSE-RT software is further enhanced through the outstanding

annual maintenance support services and user group meetings available

to all users. Ease of use contributes to minimal ramp up time,

while technical assistance contributes to minimal downtime if

problems or questions should arise.

Sample Plant Overview Display

PEPSE-RT has shown a system payback in less than one year!

The power of integrated support