Rules Engine

FAMOSTM Technology

Power & Process Products and Services

A Diagnostic Tool that Turns Data into Knowledge

In support of our industry-leading, real-time, performance and

condition monitoring products, Curtiss-Wright has developed an

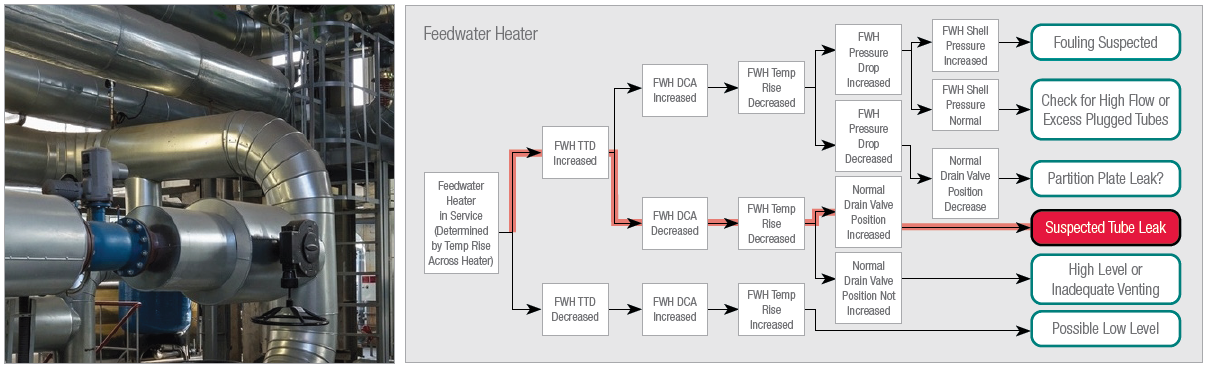

automated diagnostics application that utilizes pre-configured and/or

user developed rules that provide insight as to what the myriad of plant

and process monitoring results indicate. These assessment rules have

been developed from ASME and EPRI standards as well as from plant

experience.

The rules and calculations rely on actual monitored signals as related

to the specific equipment component or system being assessed. Rules

Engine integrates plant instrument data as well as information from

analytical applications for use as input to the rule monitoring system.

Rules Engine turns data into knowledge by providing clear

assessments for the data being monitored. This can aid organizations

where in-house, technical expertise is lost or needs supplementing.

Rules Engine provides a means for capturing and applying experienced

operational expertise to a real-time equipment monitoring environment.

It can guide operators to the root cause of reliability issues, the

source of efficiency degradations and help them understand problem

situations.

Features of Curtiss-Wright’s Rules Engine application include:

- Embedded tools for end-user to create and modify rules, edit fault calculations, and adjust rule parameters per available data

- Ability to review rule processing history, rule evaluation results, and rule calculation information

- Rules that incorporate integrated information including real-time, periodic, and off-line data

- Pre-configured rules for various fault condition assessments (Component Rules Library)

- Adaptable rules to all types of plant components, rotating, nonrotating, and electrical

Customizable Fault Tree Library

Rules Engine runs in its native server-client environment as well as a

web service to support a thin-based client deployment.

The Rules Engine product has a Component Rule Library of preconfigured

generic rules that can be easily applied to new monitoring

projects. This library presently has over eighty rules for various

types of power plant equipment. To develop a new rule for a specific

component, a user can start with a generic rule, reconfigure it as

needed, and map the appropriate inputs. More generic rules will be

added as time proceeds.

Rules Engine is one element of Curtiss-Wright’s Fleet Asset

Management and Optimization Solutions (FAMOS) suite of products

which are built on more than 40 years of power industry experience.

Combining domain expertise with advanced technology, the suite is

an integrated solution tool set for monitoring equipment, detecting

problems, analyzing anomalies, improving plant performance, and

efficiently accessing vast amounts of plant data which are the

foundation of your operation. These integrated applications provide an

in-depth approach to plant performance monitoring and optimization.

By combining Curtiss-Wright’s real-time monitoring applications (PdP

and PEPSE-RT) with periodic PdM monitoring systems, a very thorough

condition assessment can be obtained providing clear diagnostics

for plant problems. The Rules Engine application increases the value

of any and all of Curtiss-Wright’s advanced, real-time monitoring

products.

Curtiss-Wright’s system enables a truly effective and optimized

equipment condition-based maintenance initiative with:

- Utilization of multiple monitoring technologies

- True integration of all applied technologies

- Real-time information communications

- Well-defined processes

- Reliable knowledge for efficient and productive actions