SmartPlatform

FAMOS Solutions

Power & Process Products and Services

About

Curtiss-Wright is a global integrated company

with a long tradition of providing state-ofthe-

art, reliable solutions through trusted

customer relationships.

We provide analytical platforms and sensors to optimize the data you need to address plant issues. We are leaders in thermal performance software and services; equipment reliability solutions; valve condition monitoring; and advanced data analytics. We further enhance our customer support through our Monitoring and Diagnostic Center providing remote detailed evaluation of the condition of clients’ assets.

Curtiss-Wright is committed to the safe operation and improved performance and reliability of power plants worldwide.

We provide analytical platforms and sensors to optimize the data you need to address plant issues. We are leaders in thermal performance software and services; equipment reliability solutions; valve condition monitoring; and advanced data analytics. We further enhance our customer support through our Monitoring and Diagnostic Center providing remote detailed evaluation of the condition of clients’ assets.

Curtiss-Wright is committed to the safe operation and improved performance and reliability of power plants worldwide.

A Powerful Two-in-One Solution

SmartPlatform is the latest innovative solution in our customer-driven portfolio. It combines

and updates two Curtiss-Wright advanced condition monitoring applications into a single,

flexible, anomaly detection solution.

The first element of the platform is Predictive Pattern Recognition (PdP), a similaritybased, machine learning application that is time-tested and presently deployed across multiple power generation fleets. PdP functionality has been providing early warning of equipment degradation to thousands of generating assets for over 15 years.

The second component is StressWave, a sensor-based, vibro-acoustic monitoring system and associated diagnostic tools currently detecting precursor conditions prior to equipment damage on diverse assets such as cruise ships, steel mills, wind turbines, military equipment and more.

The first element of the platform is Predictive Pattern Recognition (PdP), a similaritybased, machine learning application that is time-tested and presently deployed across multiple power generation fleets. PdP functionality has been providing early warning of equipment degradation to thousands of generating assets for over 15 years.

The second component is StressWave, a sensor-based, vibro-acoustic monitoring system and associated diagnostic tools currently detecting precursor conditions prior to equipment damage on diverse assets such as cruise ships, steel mills, wind turbines, military equipment and more.

Comprehensive and Predictive Alarm System

While each of these applications can be applied independently,

leveraging their capabilities can provide superior equipment protection.

PdP has its merits for providing early warning when provided with data solely from traditional condition monitoring sensors by comparing current behavior against expected healthy behavior rather than relying on set equipment protection alarm thresholds.

StressWave supplements traditional sensors by detecting changes in vibro-acoustic emissions caused by the smallest frictional and contact events. In many cases, StressWave identified harmful conditions before any material wear occurred.

Using the power of PdP to predict the expected range of StressWave indications during normal operation permits the creation of a dynamic alarm band that provides earlier warning than fixed alarm thresholds. This means a combined system that highlights precursor conditions before any damage occurs.

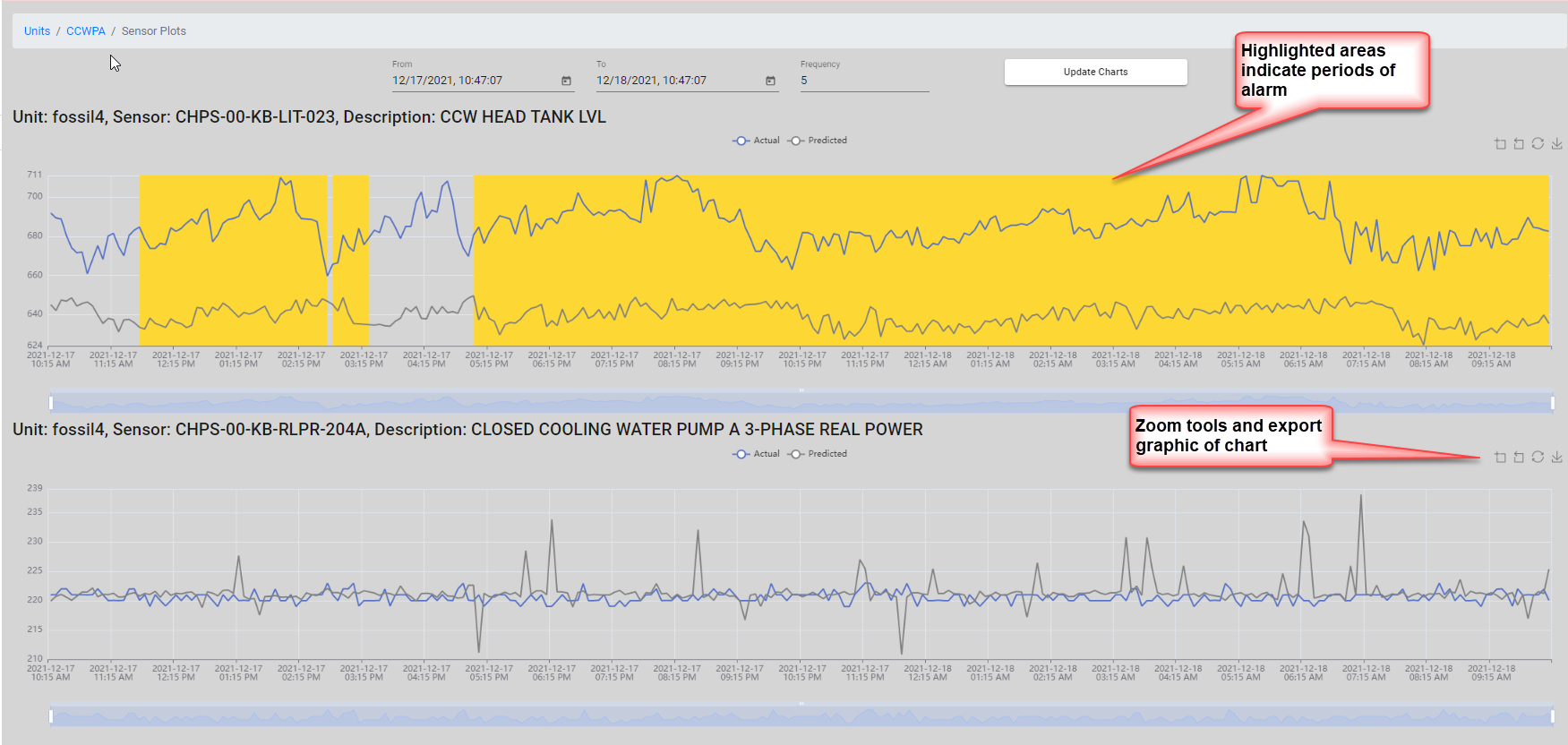

A SmartPlatform server provides real-time data collection, processing, and storage of results, as well as supporting model maintenance and storage of model configuration data. Real-time alarms and diagnostic tools are provided to end users by a web-based graphical user interface (GUI). PdP model configuration and training are accomplished on a Windows-based client networked to the SmartPlatform Server. Once configured, models run independently on the server.

PdP has its merits for providing early warning when provided with data solely from traditional condition monitoring sensors by comparing current behavior against expected healthy behavior rather than relying on set equipment protection alarm thresholds.

StressWave supplements traditional sensors by detecting changes in vibro-acoustic emissions caused by the smallest frictional and contact events. In many cases, StressWave identified harmful conditions before any material wear occurred.

Using the power of PdP to predict the expected range of StressWave indications during normal operation permits the creation of a dynamic alarm band that provides earlier warning than fixed alarm thresholds. This means a combined system that highlights precursor conditions before any damage occurs.

A SmartPlatform server provides real-time data collection, processing, and storage of results, as well as supporting model maintenance and storage of model configuration data. Real-time alarms and diagnostic tools are provided to end users by a web-based graphical user interface (GUI). PdP model configuration and training are accomplished on a Windows-based client networked to the SmartPlatform Server. Once configured, models run independently on the server.